Yushin Clamp Traverse CT Series Servo Robots

The CT and CT2 transition the former design concept of take-out robots as tools for replacing line operators to the starting point for automating part take-out. Developed from this new concept, these take-out robots provide users with the impetus to completely change the layout of their entire plant.

Yushin Single Arm Clamp End Discharge Brochure

Yushin Double Arm Clamp End Robot Brochure

Features

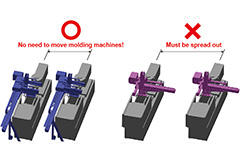

Space-efficient

Because the space between molding machines can be narrowed, more machines can be installed.

From runner take-out to product take-out

Additional space is not required to replace an existing runner take-out robot with either the CT or CT2 product take-out robot.

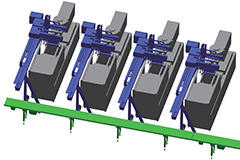

Conveyor belt centralization

Separate conveyor belts are not needed for each molding machine, therefore centralized processing can be used for packaging or inspecting molded parts.

![Energy-savings [1]](https://www.ype.co.jp/product/uploads/ycyc2-quality-1.jpg)

Energy-savings [1]

26% less power consumed than by predecessor robots

Because robot weight reduces by applying Optimum Design approach, lower duty motors are used.

![Energy-savings [2]](https://www.ype.co.jp/en/products/uploads/ctct2-quality-5en.jpg)

Energy-savings [2]

75% less air consumed than by predecessor robots

Air consumption has been reduced by 75% from predecessor models by incorporating Yushin’s propriety ECO Vacuum circuit as a standard feature.

Vibration control

72% shorter settling time than predecessor robots

With the CT and CT2 series, Optimum Design, CFRP and anti-vibration controls combine to shorten settling time (time required for vibrations to fall below a desired level) by 72%, which naturally shortens the full molding cycle.