Nissei FNX Mid-Size Hybrid Machines

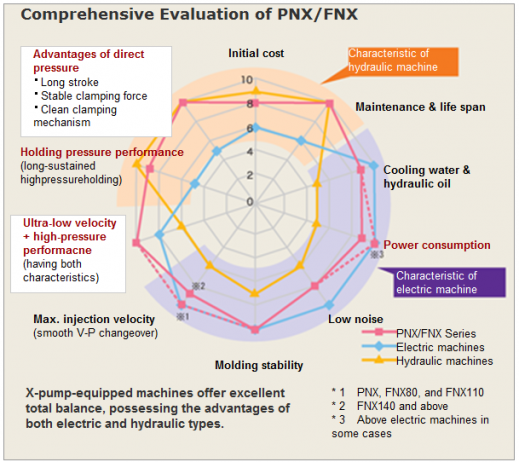

Simply put, Nissei hybrid machines offer energy efficiency comparable to all electrics but with the durability and low maintenance associated with hydraulic machines. It joins the best of both worlds making the Nissei “X” machine an extremely user-friendly, energy efficient workhorse.

Characteristics of X-Pump® Hybrid Machines

- Quick injection response

- Wide-ranging injection speed

- Stable control in ultra-low velocity range

- Long-sustained + high-pressure injection holding pressure

- High-rigidity straight-hydraulic clamping unit

- Excellent workability

- Affordable, low maintenance cost, and low running cost

- Long-lasting precision

- Excellent “clean” operation

X-Pump Details

Story Behind The X-Pump

As a driving source for injection molding machines, the hydraulic system was the main stream in the industry; however, things are changing in the past few years. Electric machines are becoming more popular because of its excellence in controllability and energy-efficiency. X-Pump is inheriting the tradition of “hydraulic advantages”, yet it is high-response, energy-efficient, low-noise, and space-saving; it can lower the operation cost. X-Pump was created to lead the Nissei Hydraulic System’s future.

1. About X-Pump

1-1 The summary of X-Pump

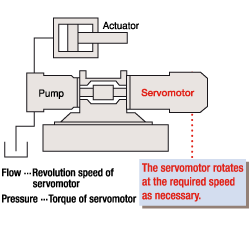

X-Pump is a new technology to overcome the disadvantages of hydraulic systems, such as noise, efficiency, and controllability (especially, repeatability and low-velocity control) issues. Similar to the load sensing and electric direct systems, the conventional hydraulic piston pump controls its pressure and flow by modulating the swash-plate angle. However, X-Pump does not control the flow by swash-plate angle, but instead it controls the pressure and flow by modulating the RPM speed of the servomotor that drives a fixed or variable displacement pumps.

1-2 X-Pump’s advantage over the swash-plate controlled conventional pumps

X-Pump’s advantage #1:

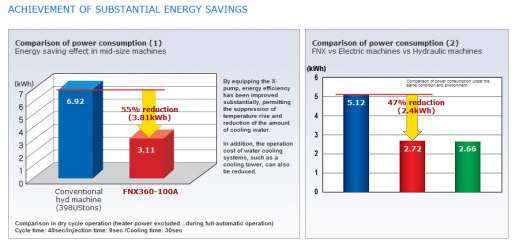

It requires no pump minimum operable pressure because the flow is controlled directly by the servomotor’s RPM. Since the servomotor’s RPM is close to zero when it is unloading, it can save a large amount of energy.

Pump Casing Drain Volume

| EH Pump | X-Pump | |

| A56 13.7MPA Pressure controlled | 3~5.5 L/M | 80~120 CC/M |

1-3 X-Pump’s other advantage

Since it drives actuators by one servomotor, pump, and conventional hydraulic elements, it has an advantage in cost performance compare to that of electric machines.

1-4 Control System

X-Pump is controlled by the special controller, goes through servo amp, and then modulates the pump. Although the setting on the conventional controller is done with analog, the new one is digital. It allows the user to set perimeter more accurately, making it easier to recalibrate and repeat.

2. Characteristics

Basic characteristics, such as noise level, are better than those of swash-plate controlled piston pump.

2-1 Response

X-Pump’s (RPM modulation) response in flow control is about two times faster than that of EH pump (swash-plate modulation). Moreover, the injection acceleration (with no load) up to 200 mm/s is 15 ms when the “preload mode” is turned off.

2-2 Noise

The noise level is low since it only requires just enough RPM to compensate the required flow volume, the motor’s RPM is close to zero when it is unloading, and X-pump can keep holding pressure without loading.

2-3 Oil Temperature

In conventional method, heat was often created by oil leak inside the pump when the motor was spinning at a constant speed (ex… unloading or holding pressure). Since X-pump’s servo motor spins only when it is needed, it can reduce the heart and downsize the tank.

ARVE Error: src mismatchprovider: youtube

url: https://www.youtube.com/watch?v=UX5GzX13G50&list=UU-yIpRb84ftyHECf1MmZ57g

src in org: https://www.youtube-nocookie.com/embed/UX5GzX13G50?list=UU-yIpRb84ftyHECf1MmZ57g

src gen org: https://www.youtube-nocookie.com/embed/UX5GzX13G50